Admixture Dispenser Discharge Line Location and Sequencing for Concrete Batching Operations – TB-0110

Cement hydration is a complex chemical reaction that begins when water is added to the concrete mix. Adding chemical admixtures to the concrete mix alters this chemical reaction in subtle and sometimes complex ways. Concrete admixtures can affect cement hydration depending upon:

- The discharge location in the batch plant,

- The point in time in the batch cycle (sequencing) at which they are discharged.

One excellent reference on the cement hydration process that also includes information on the use of admixtures is “Design and Control of Concrete Mixtures” by the Portland Cement Association.

Our dispensing equipment is used to add admixtures into the concrete mix during the batching cycle. This Technical Bulletin gives recommendations on admixture discharge line location and sequencing that should provide for the optimum performance of the admixtures. These recommendations should be followed for all new dispenser installations. For existing dispenser installations that do not conform to these recommendations, there is no need to change unless a concrete or admixture performance issue is experienced. If that does occur, a change in admixture sequencing should be tried first.

Three general rules of thumb should always be followed:

- Different chemical admixtures should not come in physical contact with one another. When certain admixtures come in contact with each other, a chemical reaction can take place that will lessen or negate their performance capabilities, or could be a safety hazard. Physical contact can take place at the end of admixture discharge lines, in a water-holding tank or in a water-discharge pipe. Of particular importance, the following should always be avoided:

- Air Entraining Agents (AEA) in contact with any set accelerators, all DCI® products and all products containing calcium chloride,

- AEA in contact with hot water (usually greater than 140°F, 60°C (ACI 306)), and

- Products containing calcium nitrite in contact with ADVA®, water reducers and/or mid-range water reducer products, which are a safety hazard.

- Individual admixtures should be added at different times (known as sequencing) during the batching operation in order to allow optimum performance.

- Continuous testing by the concrete producer is strongly recommended. If concrete testing or prior experience by the concrete producer or local salesperson has taken place before dispenser installation and has shown that different admixture discharge line location or sequencing performs better than the requirements listed below, then these requirements may be modified after discussion with a Dispenser Manager and Technical Service. Since all cements and other concrete-making materials differ from source to source, and can vary over time, continuous testing by the concrete producer is recommended for optimum admixture performance, especially when materials, admixture discharge location or sequencing change.

Dispenser Discharge Line Locations

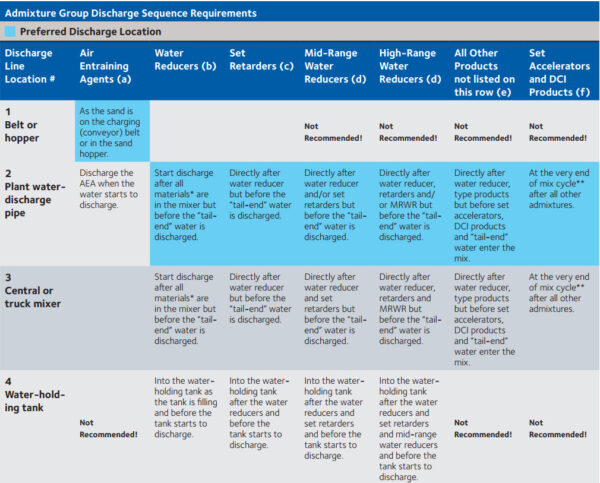

We recommend dispenser line locations #1 and 2 below, and following the “Admixture Group Discharge Sequencing Requirements” table. Location #3 is an option when #2 is not available. Location #4 is strongly discouraged and requires special approval.

- Sand Charging Belt or Weigh Hopper—Discharge Air Entraining Agents onto the sand either while on the concrete plant charging (conveyor) belt or in the sand hopper. The discharge line should be mounted such that the AEA is fully absorbed by the sand and not sprayed elsewhere. Be aware that some states’ DOT may not allow this practice and special permission may be required from them.

- Plant Water-Discharge Pipe—Install all other admixture discharge lines, including high volume products such as set accelerators and DCI products, into the plant water-discharge pipe using separate connection nozzles for each product. This pipe either originates at the plant water-holding tank or is a direct feed from the water meter. AEA may be discharged into the water discharge pipe only if a state DOT requires it, hot water will not be used, and no other admixtures are in the water at the same time. Directly Into the

- Plant or Truck Mixer—Use this option when Location #2 will not work or “tail water” is not used. When discharging directly into a mixer, care must be taken to reduce the opportunity for the discharge lines to clog due to cement dust, and ensure that they are inspected and cleaned on a regular basis.

- Water-Holding Tank—This admixture discharge location is not recommended under normal policy. Mixing of several admixtures in the water-holding tank can be a safety hazard, and/or may cause admixture and concrete performance issues. Therefore discharging certain admixtures into the concrete plant water tank is only allowed if the customer demands it, if previous testing or experience has shown this not to be a problem, and a Dispenser Manager and Technical Services approve it. Only set retarders, water reducers, mid-range water reducers and/or high-range water reducers may be discharged into the water holding tank if the above criteria have been met.

Admixture Sequencing

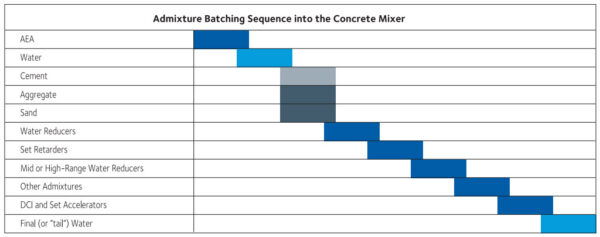

Proper sequencing of admixtures provides for optimum admixture performance. This means that different admixtures should be added to the concrete batching cycle at different times. In order to control the sequencing of admixtures, the concrete producer must program the concrete batch plant computer accordingly. Requirements for admixture sequencing are given in the table below.

* All materials means cement, other cementitious, sand, aggregate and initial water.

** This could be after the “tail-end” water enters the mix.

- Air Entraining Agents – Should be added up front in the batching process in order to allow air to build in the concrete.

- Water Reducers – Should be added after all dry materials and most of the water are added in the batching process.

- Set Retarder – Start the discharge of these admixtures immediately to follow the water reducer discharge.

- Mid-Range or High-Range Water Reducers – Start the discharge of these admixtures immediately to follow the water reducer and set retarder discharge.

- Other products:

- Set Accelerators or DCI products – Sequence the discharge of these admixtures at the tail end of the batching process using larger diameter hoses and pumps, such that discharge is fast and finishes discharging ten seconds before the end of the batching cycle.