DCI® Performance in Cracked Concrete – TB-0908

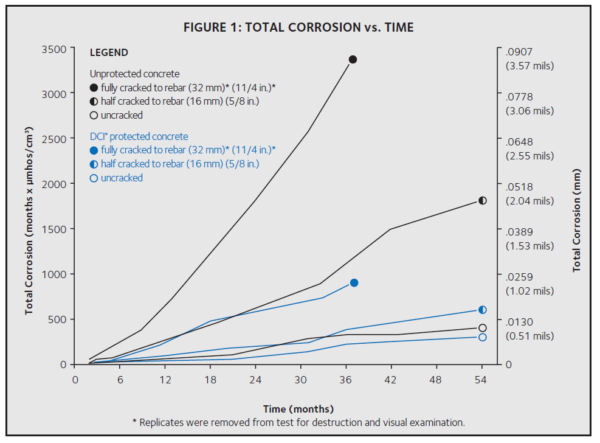

A laboratory study was conducted for three years to test DCI® Corrosion Inhibitor performance in cracked concrete. An accumulation of all corrosion measurements or total corrosion of the steel is presented here.

Three sets of specimens were produced in 100 mm x 125 mm x 405 mm (4 in. x 5 in. x 16 in.) molds with 32 mm (1 1/4 in.) of cover over a number three rebar. The first set was third point loaded to produce a crack down to the rebar, the second set loaded to produce a crack halfway down to the rebar, and the third set remained uncracked. Half the test specimens contained DCI® corrosion inhibitor at 20 L/m3 (4.0 gal/yd3) of concrete while the remaining specimens were unprotected references. All concrete had a water/cement ratio of 0.45 and an average cement factor of 410 kg/m3 (690 lb/yd3). The specimens were alternately ponded with a 3% sodium chloride solution and then dried on a weekly basis. This laboratory study is considered to be more severe than actual field conditions. Corrosion potentials, corrosion rates, total corrosion and specimen appearances were monitored every month. Concrete cracks measured .23 mm (0.009 in.) at the surface.

Figure 1

Results

- As shown in Figure 1, DCI®-protected concrete specimens have much lower total corrosion than their corresponding unprotected references.

- The fully-cracked, DCI®-protected specimens have total corrosion less than that of the unprotected half-cracked concrete specimens.

- The DCI®-protected, half-cracked to the rebar specimens have total corrosion equivalent to that of the unprotected, uncracked concrete specimens.

- The unprotected, full-cracked reference specimens have developed severe corrosion. Staining and rust-caused cracking has begun. This is in good agreement with other studies that show that over .0254 mm (1 mil) average corrosion will induce concrete cracking. The DCI®-protected, fully-cracked specimens do not show these signs of distress.

Recommendations

The use of DCI® corrosion inhibitor in concrete will help control the corrosion of steel reinforcement and strands when chlorides are present in concrete where cracking may develop.