FORCE 10,000® D Reducing Hydraulic Abrasion-Erosion – TB-0710

A durability problem facing many hydraulic structures is the abrasion-erosion of the concrete surfaces. This type of erosion is caused by any flowing water, but is especially aggravated when the water carries abrasives such as sands, gravels, silts, ice or other debris. Over time, the abrasive-laden water will erode the concrete, exposing the aggregate and producing a smooth, worn appearance on the surface. While most concrete exposed to flowing water will exhibit some wearing, structures such as dam spillway aprons, stilling basins, sluiceways and channel linings frequently experience significant deterioration and require remedial maintenance. This bulletin discusses methods of reducing the deterioration of concrete from hydraulic abrasion-erosion, particularly with respect to material design and selection. FORCE 10,000® D aids in producing a much more abrasion-resistant concrete, which economically provides added durability and design life in hydraulic structures. Additional benefits of FORCE 10,000® D concrete which provide design flexibility include: improved compressive and flexural strengths, reduced water and chloride permeability, and better resistance to chemical attack.

Test Method

Before evaluating the comparative benefits of the different materials, a standard test method must be chosen. The ACI Materials Journal1 indicates that one of the better ways of testing the abrasion resistance of concrete to waterborne particles is the U.S. Army Corps of Engineers Test CRD-C 63-80, “Test Method for Abrasion-Erosion Resistance of Concrete (Underwater Method)”. The test subjects a concrete disk to the abrasive action of steel grinding balls, which are propelled by flowing water inside the test chamber. The amount of damage, measured in terms of mass loss, is recorded periodically throughout the 72-hour test period.

Mix Design Factors

The ACI Materials Journal discusses several material design factors which should be considered in concrete exposed to hydraulic abrasion-erosion. These include the use of hard aggregates, high quality concrete, and the use of microsilica. The coarse aggregate within the concrete matrix is the component which is primarily responsible for the abrasion resistant.

Accordingly, ACI recommends that “abrasion resistant concrete should include the maximum amount of the hardest available coarse aggregate”. Cherts and trap rocks tend to be very hard and can be incorporated to provide good resistance. Additionally, good quality concrete with a relatively low water-cement ratio should be used. ACI reports test results for various types of rock and water-cement ratios, as shown in Figure 1.

Figure 1

As shown, by lowering the water-cement ratio to the 0.4 – 0.5 range and using a hard aggregate like trap rock, the abrasion-erosion loss can be reduced substantially.

Finally, ACI states “Given a good, hard aggregate, any practice that produces a stronger paste structure will increase abrasion-erosion resistance”. One good method of improving the paste is incorporating FORCE 10,000® D into the mix. The tiny microsilica particles completely surround cement particles and fill in voids, creating a tighter paste. These pozzolanic particles also react with the weak, free lime within the matrix, converting it into calcium- silicate-hydrate, or glue, which provides increased aggregate bonding within the system.

FORCE 10,000® D Test Results

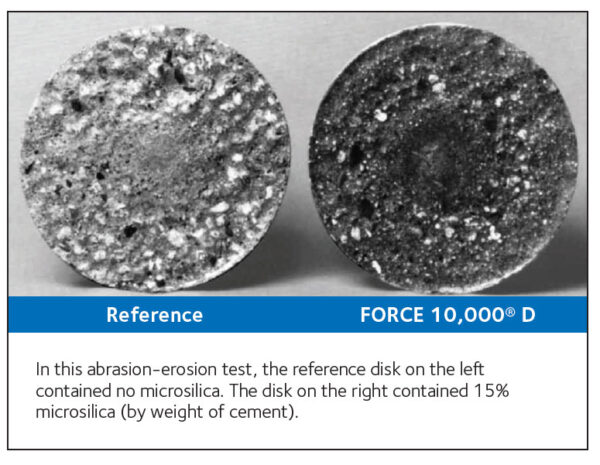

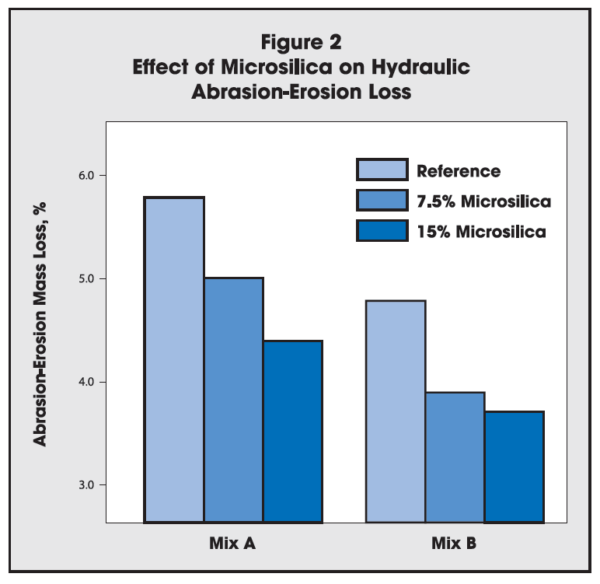

Figure 2

We have performed the Corps of Engineers test on several mix designs incorporating FORCE 10,000® D with very positive results. Two sets of results with different mix designs are shown in Figure 2 above. The FORCE 10,000® D specimens in both mixes showed significantly less mass loss than the references, which contained no FORCE 10,000® D. FORCE 10,000® D produces a much stronger, more abrasion-resistant paste. The photograph shown at right compares two samples undergoing the test (one reference and one with 15% microsilica), and reveals the effect of the stronger paste with FORCE 10,000® D. In addition, the paste produces a much stronger bond to the aggregate, reducing the potential for aggregate pop-outs from cavitational effects. Even when good strong aggregates are not locally available, FORCE 10,000® D can be used to produce high-strength concrete which is abrasion-resistant, overcoming problems with unsatisfactory aggregate. In such concretes, ACI states that apparently “the hardened cement paste assumes a greater role in resisting abrasion-erosion damage and the aggregate quality becomes correspondingly less important”. Use of FORCE 10,000® D can then provide economic benefits versus the importation of outside aggregates.

Dosage Considerations

Summarizing the material design recommendations, it is important to get the maximum amount of the hardest available coarse aggregate into the mix. The lowest practical water-cement ratios should be used, coupled with a superplasticizer to provide adequate workability. FORCE 10,000® D dosages between 7.5% and 15% (percent microsilica by weight of cement) are generally sufficient to give the added durability. Your representative can provide assistance in designing the appropriate mix to meet specific design criteria.

Current Usage

Microsilica concrete is beginning to gain broader acceptance in hydraulic applications as the industry becomes more aware of its benefits. One of the first applications in the U.S. was Pennsylvania’s Kinzua Dam stilling basin, which suffered severe abrasion-erosion deterioration since its completion in 1967. After extensive laboratory investigations, the Corps of Engineers in 1983 elected to use microsilica concrete for added durability. In 1985, the Corps again selected microsilica concrete to reline the Los Angeles River Basin channel, a critical passageway which carries of the river’s seasonal flow. More recently, FORCE 10,000® D has been used on dams in Maine and Kansas, and is being tested in Oregon for channel lock linings to provide increased abrasion-erosion resistance.

FORCE 10,000® D can be used to produce more durable, abrasion-resistant concrete for hydraulic structures.