The Effects of DCI® on the Corrosion Rates of Steel in Concrete – TB-0907

A Laboratory Study

In 1984 the latest large scale accelerated corrosion test program was initiated examining the effects of concrete mix design and DCI® Corrosion Inhibitor on the corrosion resistance of steel. An accumulation of all corrosion measurements or total corrosion of the steel is presented here in order to show how rebar corrosion affects concrete deterioration. This study used 75 mm (3 in.) diameter by 150 mm (6 in.) high “lollipops” partially submerged in a 3% sodium chloride solution. The “lollipop” (Figure 1) consisted of a No. 3 [9.5 mm diameter (3/8 in.)] rebar embedded in concrete cylinders. Concrete cover over the rebar remained constant at 33 mm (1.3 in.) with the variables being water/cement ratio and the amount of DCI®.

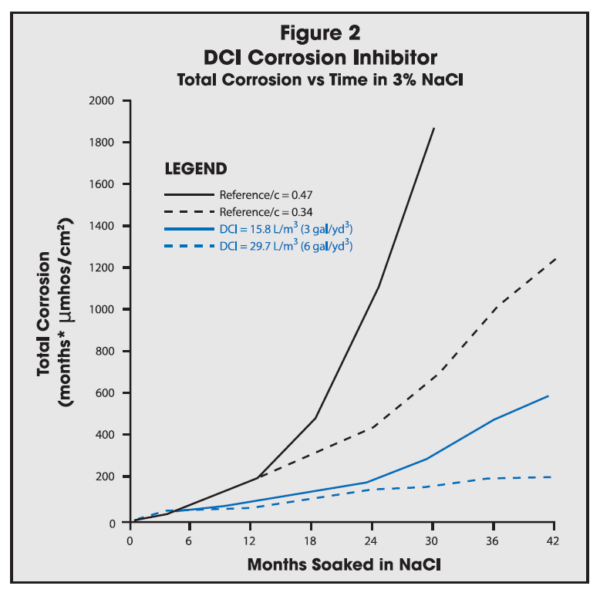

Corrosion rates were measured every three months for the first two years and then at 6 month intervals using polarization resistance techniques (correcting for concrete resistance). By adding these measurements (integrating over time), total corrosion is determined as shown in Figure 2.

A total corrosion measurement of 1000 µmho-month/cm2 is roughly equivalent to 1 mil average depth of corrosion on the steel. This is considered enough to cause rust staining or cracking of the concrete at localized sites. Chloride levels were also measured at different “lollipop” vertical elevations throughout the test program.

Conclusions

DCI® significantly improves the corrosion resistance of steel in concrete, especially below water/cement ratios of 0.50.

Figure 1

Figure 2

- DCI® – protected concrete, at a water/cement ratio of 0.45, has lower total corrosion than unprotected concrete with a water/cement ratio of 0.34.

- Chloride levels are significantly reduced by lowering the concrete water/cement ratio.

When corrosion begins at high chloride levels in DCI® concrete, the corrosion rate is lower than corrosion rates in unprotected concrete. - DCI® protects at chloride to nitrite ratios exceeding 1.5:1.0 by weight, based on original nitrite content.

- Visual analysis of autopsied rebars confirmed that when the polarization resistance technique indicated corrosion, there was indeed corrosion product on the steel. High corrosion rate measurements correlated with more rust product.

This Technical Bulletin 0907 is based on “The Effects of Calcium Nitrite and Mix Design on the Corrosion Resistance of Steel in Concrete Results”, by Dr. N. S. Berke, which was published in NACE’s Corrosion — March 1987, and continuation of these experiments.