Using ADVA® FLEX – TB-0607

ADVA® FLEX is a polycarboxylate-based, ASTM C494 Type F high-range water reducer, developed to allow a concrete producer to adjust the concrete slump retention to meet a project requirement with minimal impact on other concrete properties. It is recommended primarily for use in ready mix applications where improved slump retention is desired due to hot ambient conditions, long haul times or where job site retempering is not allowed or desired. ADVA® FLEX may be added to a concrete mix in a manner similar to other polycarboxylate-based superplasticizers. This technical bulletin provides general information on plastic and hardened properties of concrete made with ADVA® FLEX.

Addition Rates

ADVA® FLEX dosage rates range from, but are not limited to, 260–910 mL/100 kg (4–14 oz/100 lbs) of total cementitious and will vary depending on desired slump retention, mix design specifics, material properties, and ambient and concrete temperatures. As the dosage rate of ADVA® FLEX increases to 520 mL/100 kg (8 oz/100 lbs) and higher, the slump retention increases dramatically, and the concrete time of setting and water reduction increase to a lesser degree. There is minimal impact on other plastic and hardened concrete properties.

Slump Retention

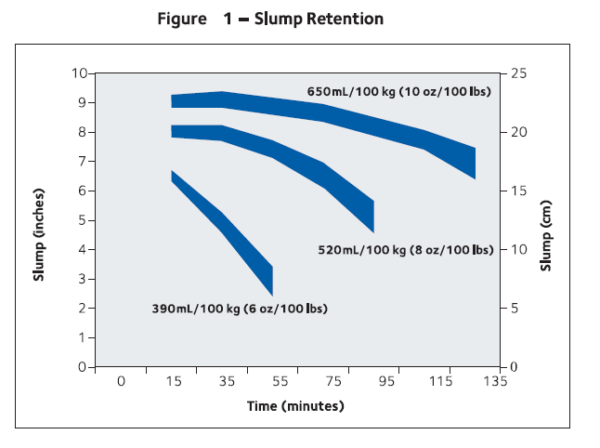

The major benefit of ADVA® FLEX is the improvement in slump retention as the dosage rate is increased. Figure 1 shows the slump retention curves for three dosage rates of ADVA® FLEX for multiple ready mix tests with materials between 27 to 32°C (80 to 90°F) concrete temperatures. Since local concrete materials, and ambient and concrete temperatures will be different than those used in Figure 1, these curves will differ accordingly.

Mix Proportioning

ADVA® FLEX may be used with a variety of concrete making materials, water-to-cementitious ratios and ambient conditions and may be added to the concrete batch process in a manner similar to other polycarboxylate-based superplasticizers. As with all admixtures, testing should be performed before concrete production to ensure compatibility and performance.

Water Reduction

At 390 mL/100 kg (6 oz/100 lbs), ADVA® FLEX meets ASTM C494 Type F superplasticizer requirements and ASTM C1017 Type I plasticizing. ADVA® FLEX, primarily a slump-retaining admixture, may not always be able to replace a traditional superplasticizer at the 390 mL/100 kg (6 oz/100 lbs) dosage rate. However, water reduction will continue to increase as dosage rates are increased. At higher ADVA® FLEX dosage rates, it may be necessary to slightly reduce the water content of the mix design in order to achieve target initial slump without segregation.

Air Entrained Concrete

ADVA® FLEX was extensively field tested in a wide range of air entrained concrete mix designs, and consistently provides stable and good quality air void systems. Air-entraining agent (AEA) dosage rates for ADVA® FLEX concrete will be similar to or higher compared to most polycarboxylate-based superplasticizers. Trial mixes are recommended to dial in AEA dosage rates for a specific mix design, especially if different dosage rates are planned.

Concrete Time of Setting

ADVA® FLEX times of setting will gradually increase as dosage rates are increased to provide greater slump retention. At dosage rates of 520–650 mL/100 kg (8–10 oz/100 lbs), ADVA® FLEX times of setting typically range from 30 to 60 minutes longer than most polycarboxylate-based superplasticizers. Alternatively, a set retarder could be used to extend the slump life of the concrete with a conventional superplasticizer but it may also extend the concrete time of setting beyond that of ADVA® FLEX concrete for the same workability. In cooler climates, lower ADVA® FLEX dosage rates 390–520 mL/100 kg (6–8 oz/100 lbs) should be utilized for increased slump retention if near-neutral time of setting properties are required.

Concrete Strength and Hardened Properties

The dispersion properties of ADVA® FLEX result in excellent early and later age compressive and flexural strengths that are equal to or greater than other polycarboxylate-based superplasticizers. Increased compressive strengths up to 3.5MPa (500 psi) have been realized with some materials at higher ADVA® FLEX dosage rates.

Local Trial Mix Testing

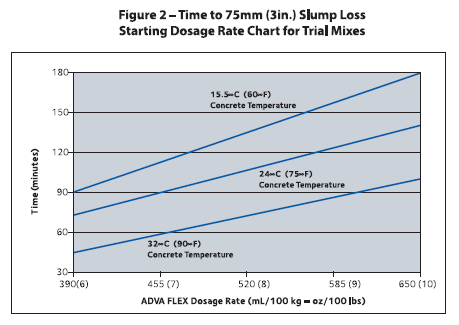

All admixtures will perform differently with different concrete making materials. Before ADVA® FLEX is used in everyday concrete production, we strongly recommend that this product be tested with local materials in all mix designs that it will be used in and tested again as concrete making materials or ambient conditions change. Figure 2 may be used to choose a starting dosage rate prior to running trial mixes to confirm slump retention properties. It depicts estimated time from concrete batching to a slump loss of approximately 75 mm (3 in.) as a function of ADVA® FLEX dosage rate (range from 390–650 mL/100 kg (6–10 oz/100 lbs)) and three concrete temperatures (15°C, 24°C and 32°C (60°F, 75°F and 90°F)). Concrete making materials (especially cement and pozzolans), various admixtures included in the mix design, and production and environmental specifics will all affect these curves and should be taken into account when running trial batches.

Compatibility with Other Admixtures

ADVA® FLEX is compatible with most admixtures as long as they are added separately to the concrete mix. However, ADVA® FLEX is not recommended for usage in concrete containing naphthalene-based admixtures including

DARACEM® 19 and DARACEM® 100, and melamine-based admixtures including DARACEM® ML 330 and DARACEM® 65.

Admixture Addition and Sequencing

It is recommended that ADVA® FLEX be added to the concrete mix at the end of the batch sequence for optimum performance. However, it may be added at other times in the batching sequence if testing shows acceptable performance. Pre-testing of the concrete should be performed to optimize addition rates and sequence times of these admixtures. Admixtures should be added separately and not contact each other before they enter the concrete mix.