Using ADVA® XT2 – TB-0609

ADVA® XT2 is recommended primarily for use in ready mixed concrete applications where improved slump life is desired or required due to hot ambient conditions, long haul times and tight slump specifications. ADVA® XT2 dosage rates typically range from 4 to 6 oz/100 lbs (260 to 390 mL/100 kg) of cementitious and will vary depending on mix design specifics, slump life requirements, and ambient and concrete temperatures. ADVA® XT2 can be used with most other admixtures including standard, mid-range and high range water reducers, accelerators, retarders, air entraining agents and specialty admixtures. ADVA® XT2 is also fully compatible in mix designs containing pozzolans including flyash, slag and silica fume. This technical bulletin details recommended best practices for ADVA® XT2 field usage and plastic and hardened properties of several field tested ADVA® XT2 mix designs.

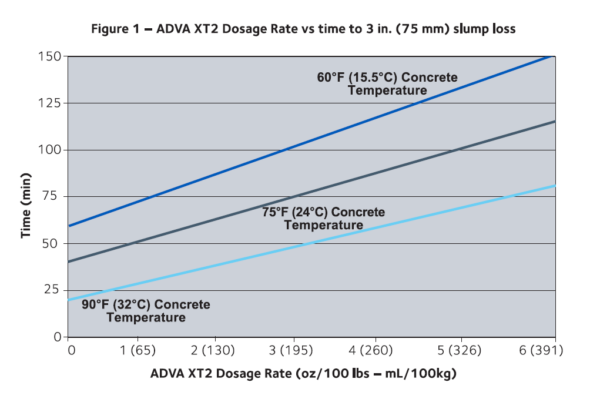

Slump Retention

Figure 1, below, depicts estimated time (from concrete batching) to approximate 3 in. (75 mm) of slump loss as a function of ADVA® XT2 dosage rate. This graph may be utilized to select a starting point for ADVA® XT2 dosage rates prior to running trial mixes to confirm slump retention properties with a specific mixture and set of materials. Several factors including cement/pozzolan type and properties, other admixtures and various production and environmental conditions can also significantly impact slump life properties.

Water Reduction

ADVA® XT2 meets the requirements of ASTM C494 as a Type A water reducer. Water reduction can be expected to slightly increase as dosage rates increase. Therefore, at higher ADVA® XT2 dosage rates, it may be necessary to either cut water content slightly or reduce base water reducer or superplasticizer dosage rate.

Compressive Strength

At equal water contents, ADVA® XT2 will have a negligible impact on early and later age compressive and flexural strengths compared to the base mix. If water contents are reduced to compensate for ADVA® XT2 water reduction properties, a proportionate strength gain will be noted.

Set Time

The addition of ADVA® XT2 will extend the initial setting time, on average from 0 to 50 minutes. Impact on set time will depend on the addition rates, mixture proportions, and ambient and concrete temperatures.

Air entrained concrete

ADVA® XT2 has been extensively field tested in a wide range of air entrained concrete mix designs and consistently demonstrated stable and good quality air void systems. Typically, AEA dosage rates for ADVA® XT2 concrete will be similar to the base mix without ADVA® XT2. Again, trial mixes are recommended to establish AEA dosage rates and air content variation over time for a specific concrete mixture.

Compatibility with other admixtures

ADVA® XT2 is a polycarboxylate based technology and therefore is fully compatible with most other admixtures. However, ADVA® XT2 is not recommended for usage in concrete containing naphthalene (NFSC) based admixtures including Daracem® 19.

Table 1 – Examples of ADVA® XT2 North America Field Performance

| Cool Climate Non air entrained Concrete |

Moderate Climate Non air entrained Concrete |

Hot Climate Non air entrained Concrete |

||||

| Reference | ADVA® XT2 | Reference | ADVA® XT2 | Reference | ADVA® XT2 | |

| Mix Design Specifics lbs/yd3 (kg/m3) |

648 (384) cement 293 (174) H2O 1304 (774) 3/4 in. CA 574 (340) 3/8 in. CA 1362 (808) FA |

646 (383) cement 294 (174) H2O 1327 (787) 3/4 in. CA 575 (341) 3/8 in. CA 1340 (795) FA |

615 (365) cement 257 (152) H2O 1203 (714) 3/4 in. CA 505 (300) 3/8 in. CA 1415 (839) FA |

615 (365) cement 257 (152) H2O 1203 (714) 3/4 in. CA 505 (300) 3/8 in. CA 1415 (839) FA |

568 (337) cement 275 (164) H2O 1767 (1048) 1 1/2 in. CA 1381 (819) FA |

585 (347) cement 277 (164) H2O 1762 (1045) 1 1/2 in. CA 1371 (813) FA |

| Admixtures oz/100 lbs (mL/100 kg) |

5 (326) ADVA 190 Reference |

5 (326) ADVA 190 3 (195) ADVA® XT2 |

6 (391) ADVA 190 Reference |

5 (326) ADVA 190 5 (326) ADVA® XT2 |

12 (782) ADVA 140(M) Reference |

12 (782) ADVA 140(M) 5 (326) ADVA® XT2 |

| Concrete Temp °F (°C) | 65°F (18°C) | 63°F (18°C) | 85°F (29°C) | 87°F (31°C) | 90°F (32°C) | 91°F (33°C) |

| Ambient Temp °F (°C) | 40°F (4°C) | 40°F (4°C) | 76°F (24°C) | 80°F (27°C) | 89°F (32°C) | 89°F (32°C) |

| Time (minutes) to final slump |

60 | 175 | 55 | 95 | 55 | 95 |

| Initial Slump in. (mm) | 8.75 (222) | 9 (229) | 9.5 (241) | 8.75 (222) | 8 (203) | 9 (229) |

| Final Slump in. (mm) | 4 (102) | 5 (127) | 3.25 (82) | 3.5 (89) | 4.25 (108) | 4.5 (114) |

| Initial Air (%) | 1.5% | 1.5% | 1.7% | 2.0% | 5.5% | 5.7% |

| Final Air (%) | 2.5% | 2.3% | 2.2% | 2.3% | 5.8% | 3.5% |

| 7 Day Compressive Strength psi (MPa) |

6284 (43.3) | 5890 (40.6) | 5405 (37.3) | 5250 (36.2) | 3300 (22.7) | 3690 (25.4) |

| 28 Day Compressive Strength psi (MPa) |

7456 (51.4) | 7833 (54.0) | 6655 (45.9) | 6560 (45.2) | ||

| Set Time (hrs:min) | 9:00 | 10:20 | 4:10 | 3:30 | 3:05 | 3:03 |