Award-winning concrete project uses a collaborative eco-innovation approach for the win

The new Seattle Storm Center for Basketball Performance will serve as the dedicated practice facility for the four‐time WNBA championship team the Seattle Storm.

The building’s design includes two side‐by‐side basketball courts, the “Storm Team Center” with locker rooms, a lounge and a nutrition center for the players, strength and conditioning training spaces, and the franchise’s business offices.

The facility will both celebrate the Storm’s success in Seattle and allow the franchise to expand its efforts to grow opportunities for female athletes and youth in the city.

The facility will both celebrate the Storm’s success in Seattle and allow the franchise to expand its efforts to grow opportunities for female athletes and youth in the city.

The state‐of‐the‐art professional basketball facility is being built on a 50,000‐square‐foot parcel in Seattle’s Interbay neighborhood. The project involved tilt-up construction with sandwich panels and is designed to achieve LEED Gold, with all‐electric operations and a rooftop photovoltaic array.

Aggressive low carbon concrete requirements are a primary design feature of the structure. In March 2024 the National Ready Mixed Concrete Association (NRMCA) recognized the project’s outstanding achievements in eco-friendly low-carbon concrete with a 2024 Concrete Innovations Award. This award celebrates accomplishments in the design and construction of concrete structures. Winners represent building and infrastructure projects substantially designed and built using concrete and having improved all-around performance, including reduced carbon footprint.

The Challenges

The project had numerous technical challenges to meet low CO2 requirements and achieve LEED Gold, as well as keeping the construction schedule on track.

The project’s concrete producer, Stoneway Concrete, was initially approached by the contractor, Sellen Construction, with the request for white cement concrete for the exterior tilt-up walls. The requirements from the specifier included limits on embodied carbon and maximum cement limits. The alternatives: white cement (carbon reduction and cost) and pigments (cost) could not be achieved. Sellen Construction had placed an 80% slag cement mix on a previous project and was aware that it produced a very light color after curing.

Stoneway met with Sellen to discuss the challenges of the low carbon concrete and to discuss the finishing and curing methods required for these unique mix designs. This was followed up by several mockup pours that allowed the construction team the ability to place and finish the 80% slag mixes and practice the sandwich panel installation required by the design team.

The Solution

To address the technical issues head on, the teams came together to use an eco-innovation approach. During the construction process, Sellen and Stoneway collaborated to solve the challenges the mixes gave to the placing and finishing team, while only needing to make minor adjustments to the concrete mix.

To maximize slag cement content and ASTM C595 type IL cement for various applications on the job, the design and construction team worked together to identify areas, like the foundations and tilt-up walls, where concrete could be specified with 56 day design, rather than 28 days, further reducing the required amount of cementitious ingredients and Global Warming Potential (GWP) to achieve required strength.

Stoneway utilized Lafarge slag cement, Ashgrove type IL cement, and selected Chryso’s admixture and fiber technologies to help exceed the specified embodied carbon limits and overall performance. Stoneway collaborated with Chryso to identify the best low carbon mixes for the intended application. The following admixtures were selected:

- STRUX 75/32 MACRO FIBERS: Used in the panels to improve durability and long-term crack control

- CONCERA All-in-One Admixture and ADVA High-Range Water Reducers: Enabled the use of local materials, helping to boost sustainability and minimize need for vibration due to high flow, making it easy to place and finish and produce high strengths

Exceeding Expectations

Stoneway was able to propose concrete mixtures that met the architect’s requirement for color, and that met the structural and design requirements. Those included:

- 6,000 PSI at 56 days (500 PSI Flexural at 28 days)

- Tilt panels required 4,000 PSI to tilt. Giatec Smart Rock maturity sensors were able to show the contractor they met the requirement in 3 days

- 3,000 PSI at 28 days (500 PSI Flexural) for the exterior “beauty panels” required Macro fibers to replace WWF, and make consolidation easier

- All concrete required .040% drying shrinkage at 28 days

“We had solutions that might not be obvious,” says Stoneway Concrete Technical Services Manager Michael Gardner. “However, as we were armed with detailed knowledge of the locally available materials, their potential impact and mix optimization expertise, we were able to get creative and ultimately exceed everyone’s expectations for both performance and CO2 reduction. No doubt the ability to quantify our decisions through CO2 impact using EPDs strengthened the validity of our plan.”

The Results

The construction of the Seattle Storm Center for Basketball Performance was recently included in The Seattle Times article “Northwest Innovators Chase the Dream of Greener Concrete.” It’s a leading example of how early collaboration may achieve an eco-innovation construction approach, reducing the amount of carbon in concrete throughout the product life cycle:

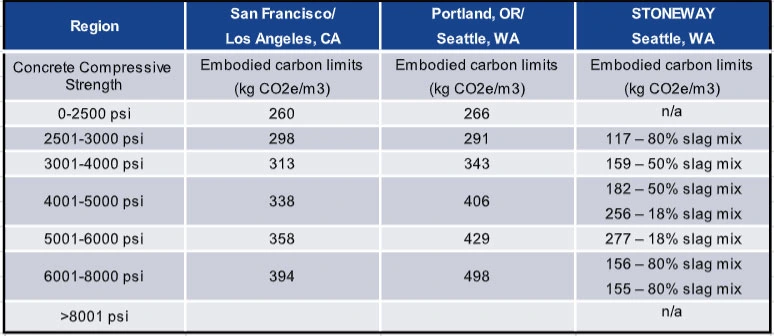

- 3,000 PSI at 28 days “beauty panels” using CONCERA/ADVA/STRUX – GWP of the mix 118 (kg CO2e/m3) specified 291 (kg CO2e/m3)

- 6,000 PSI at 56 days ADVA/VMAR 3 – GWP of the mix 155 (kg CO2e/m3) specified 429 (kg CO2e/m3), 4,000 PSI at 3 days (using maturity sensors)

- 27% of the concrete on the project utilized 80% slag cement, 64% of the concrete utilized 50% slag cement.

Overall the project exceeded a 40% reduction compared to typical average mixes in the region, and achieved 80%* of the 2030 targeted reductions of the First Movers Coalition for concrete.

Together the teams collaborated to uncover a novel set of solutions to exceed the low carbon concrete project requirements and accomplish LEED Gold. “We knew we would be faced with numerous technical concrete challenges on the Seattle Storm project, so it was important to begin collaboration early with the design and construction team,” says Stoneway Concrete General Manager Greg McKinnon. “Establishing confidence in our expertise and consensus within the team was key to our success.”

Recognized by the NRMCA as one of the top eco-friendly low-carbon concrete projects in 2024, the Seattle Storm Center for Basketball Performance is paving the way for more structures to prioritize sustainability for the entire life cycle of the building.

Project Participants

Project: The Seattle Storm Center for Basketball Performance

Design Architect: Shive-Hattery

Architect of Record: ZGF

Concrete Producer: Stoneway Concrete

Contractor: Sellen Construction

Structural: Holmes